Do you feel prepared to advance the capability of your industrial equipment?If you’re involved in the manufacturing or maintenance of industrial machinery, then you already know the crucial role that PCB (Printed Circuit Board) design and development plays in ensuring the efficiency, reliability, and performance of these complex systems. In this article, we’ll dive deep into the world of pcb design and development for industrial equipment, providing you with valuable insights and suggestions to help you stay ahead in this ever-evolving field.

Understanding the Essence of PCB Design and Development:

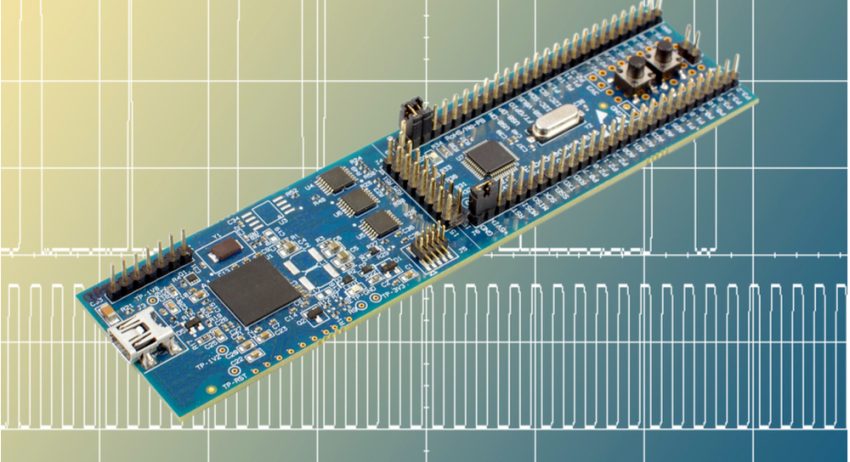

Before we delve into the specifics, let’s revisit the fundamentals of PCB design and development. In the realm of industrial equipment, PCBs are the heart and soul of electronic control systems. These intricate boards house a network of components, including microcontrollers, sensors, and power management circuits, which collectively govern the operation of the machinery. Efficient PCB design is paramount to achieving optimal functionality and performance.

Key Considerations in PCB Design for Industrial Equipment:

- Reliability is King: When it comes to industrial machinery, downtime can result in significant losses. Hence, the reliability of your PCBs should be a top priority. Opt for high-quality materials and rigorous testing to ensure longevity and minimize the risk of failure.

- Size Matters: Industrial equipment often demands compact and space-efficient PCBs. Collaborate with experienced PCB designers who can balance functionality with size constraints without compromising performance.

- Scalability and Future-Proofing: Industrial equipment evolves. Plan for scalability in your PCB design, allowing for future upgrades and modifications without the need for a complete overhaul.

The Role of Advanced Technologies:

In the rapidly advancing world of electronics, staying up-to-date with the latest technologies is essential. Incorporating innovations like IoT connectivity, predictive maintenance algorithms, and real-time data analytics into your PCB design can greatly enhance the performance and efficiency of your industrial equipment.

In the realm of industrial equipment, pcb design and developmentare the backbone of innovation and progress. By prioritizing reliability, considering key factors, embracing advanced technologies, and fostering collaboration, you can unlock the full potential of your machinery. Remember that the right PCB development partner can make all the difference in achieving success.

As you embark on your journey to enhance your industrial equipment, keep these insights in mind. PCB design and development are not just technical aspects; they are a gateway to improved efficiency, reduced downtime, and ultimately, greater profitability in the world of industrial machinery.